NICEIC-Approved. Industry Ready.

Singleton Engineering Solutions provides responsive and experienced electrical support for industrial systems across the UK. Whether you’re installing new machinery, integrating controls, or resolving a sudden breakdown, we offer trusted hands-on service with rapid response and complete transparency.

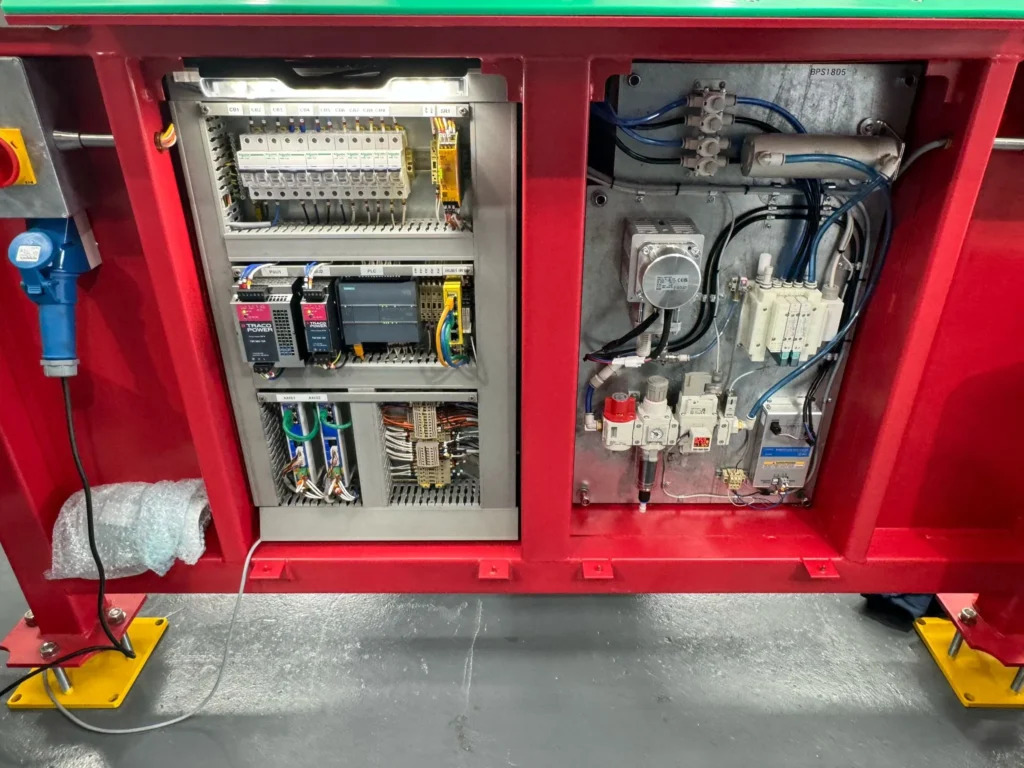

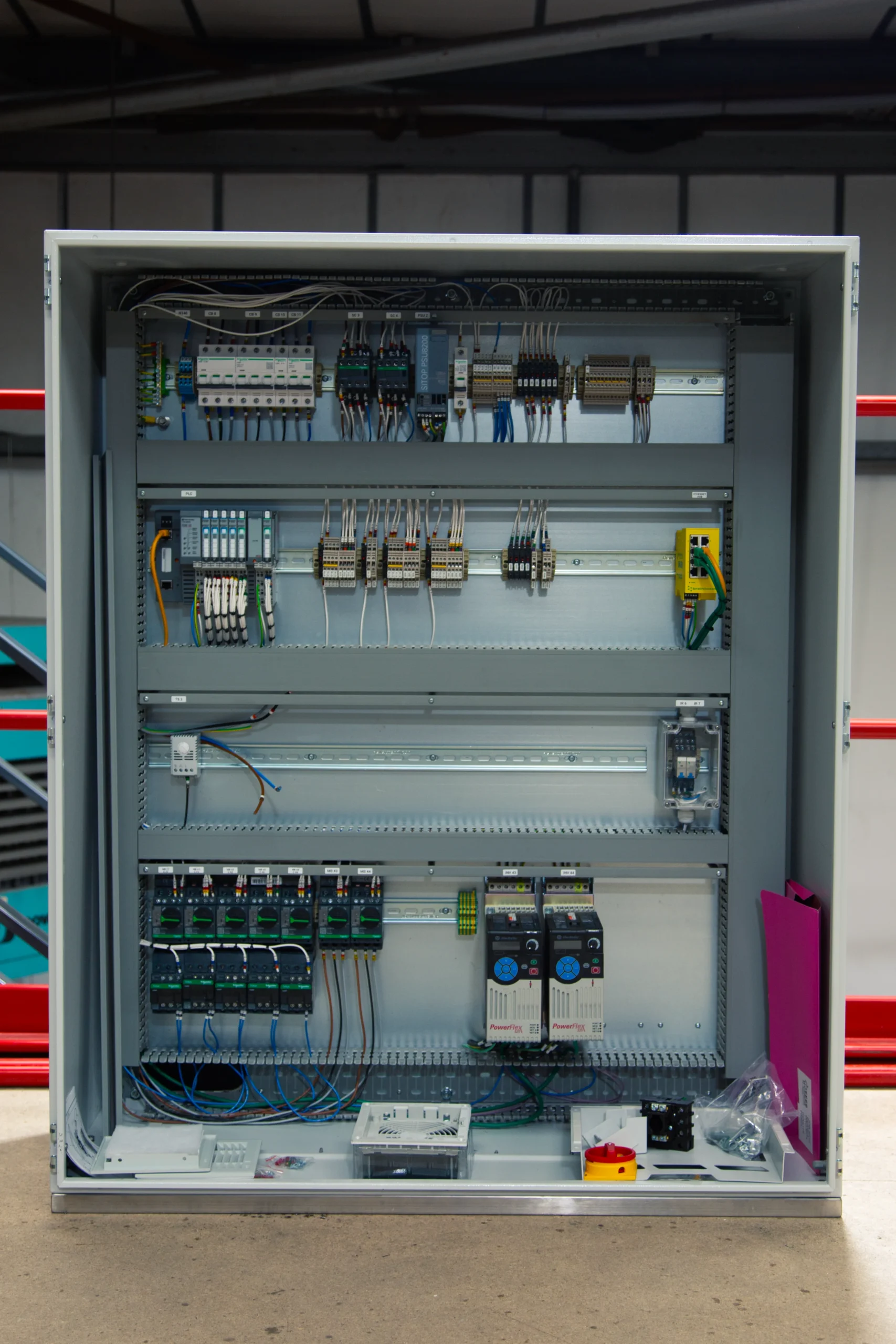

We specialise in working with equipment that includes Programmable Logic Controllers (PLCs), three-phase power and custom control panels, delivering full electrical support across manufacturing, packaging and process lines.

Our team of qualified engineers supports a wide range of automated systems, including conveyors, packaging lines, filling machines and product handling equipment. We design and fit electrical interfaces that integrate seamlessly into your operation, so that each element talks to the next without delays or misfires.

We’ve worked in everything from live food production sites to complex logistics hubs, bringing electrical experience to fast-paced, high-pressure environments. Whether you need reactive troubleshooting, fault finding or a system upgrade, we deliver safe, practical and compliant solutions.

Our team has extensive experience with PLC-based systems, both modern and legacy. We can modify existing programs, replace failed modules, or support the design and integration of brand-new systems. Where required, we also work alongside your software vendor or in-house automation team to ensure smooth deployment.

From full cabinet builds to basic interface wiring, we cover all aspects of machine-level electrical work, helping your mechanical and software systems operate in sync.

We also provide fault isolation and testing support when dealing with inconsistent outputs, drive failures, or power drops, giving you a faster route to resolution.

All our electrical engineers are NICEIC-approved, fully trained in industrial safety protocols and familiar with both high and low voltage systems. We carry out every job with attention to safety, professionalism and a clear understanding of your site’s compliance requirements.

We communicate openly throughout the repair or installation process, keeping your team informed and minimising downtime wherever possible.

We also carry out testing, certification and remedial work to ensure installations meet regulatory standards and site-specific requirements.

What makes Singleton different is our ability to provide electrical, mechanical and fabrication services all under one roof. This gives you a single point of contact and a joined-up team that understands every part of your operation, from the steelwork to the signal.

If your project involves machine relocation, power supply upgrades, conveyor installations or access platforms, we’ll deliver the entire package. It means faster delivery, clearer communication and a simpler experience for your team.

We also offer long-term support contracts, planned inspections and ad-hoc callouts, giving you flexibility without compromising service.

What makes Singleton different is our ability to provide electrical, mechanical and fabrication services all under one roof. This gives you a single point of contact and a joined-up team that understands every part of your operation, from the steelwork to the signal.

If your project involves machine relocation, power supply upgrades, conveyor installations or access platforms, we’ll deliver the entire package. It means faster delivery, clearer communication and a simpler experience for your team.

We also offer long-term support contracts, planned inspections and ad-hoc callouts, giving you flexibility without compromising service.

Singleton Engineering Solutions design, fabricate, install, and maintain bespoke machinery, steelwork and engineered systems for manufacturers, food producers, and industrial firms across the UK.

Copyright © 2025 Singleton Engineering Solutions.

Site managed by Rank Kings