Mechanical Engineering

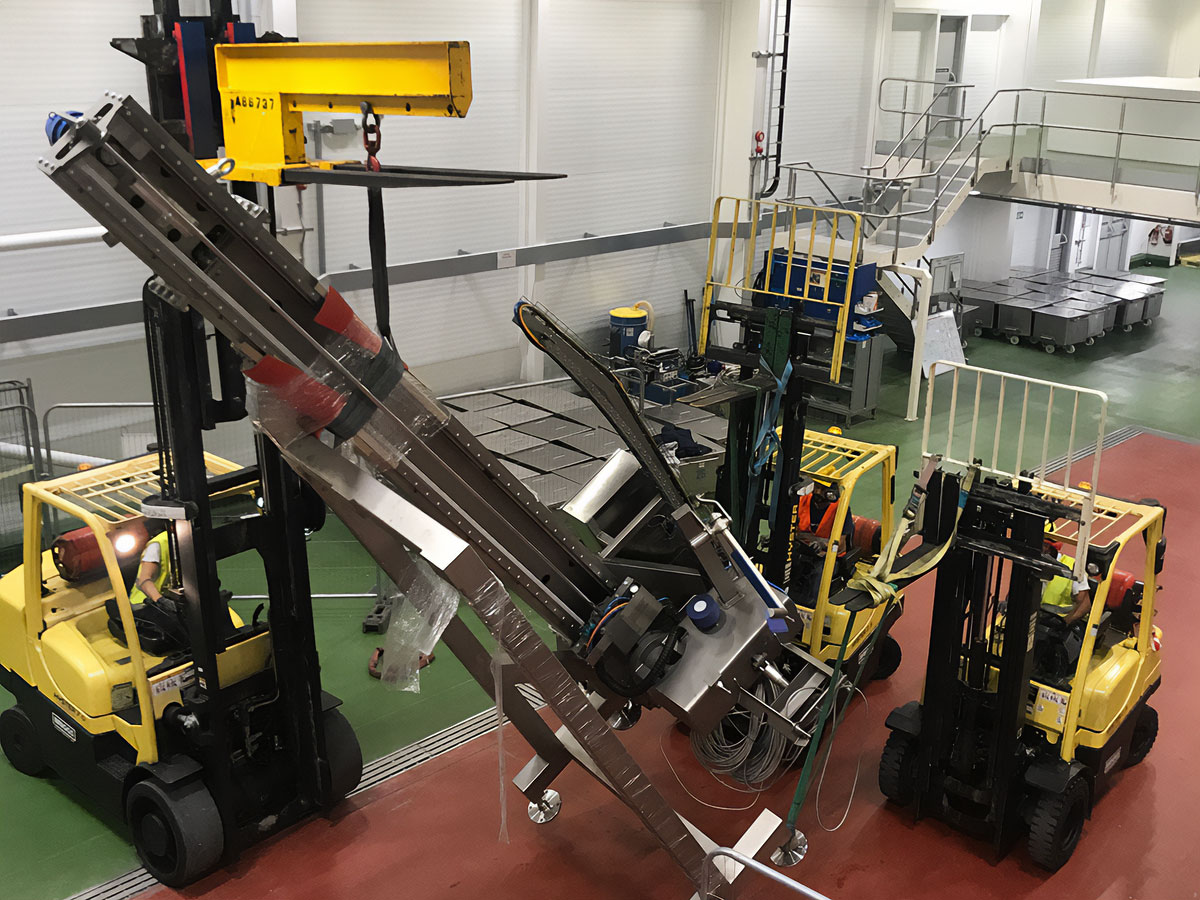

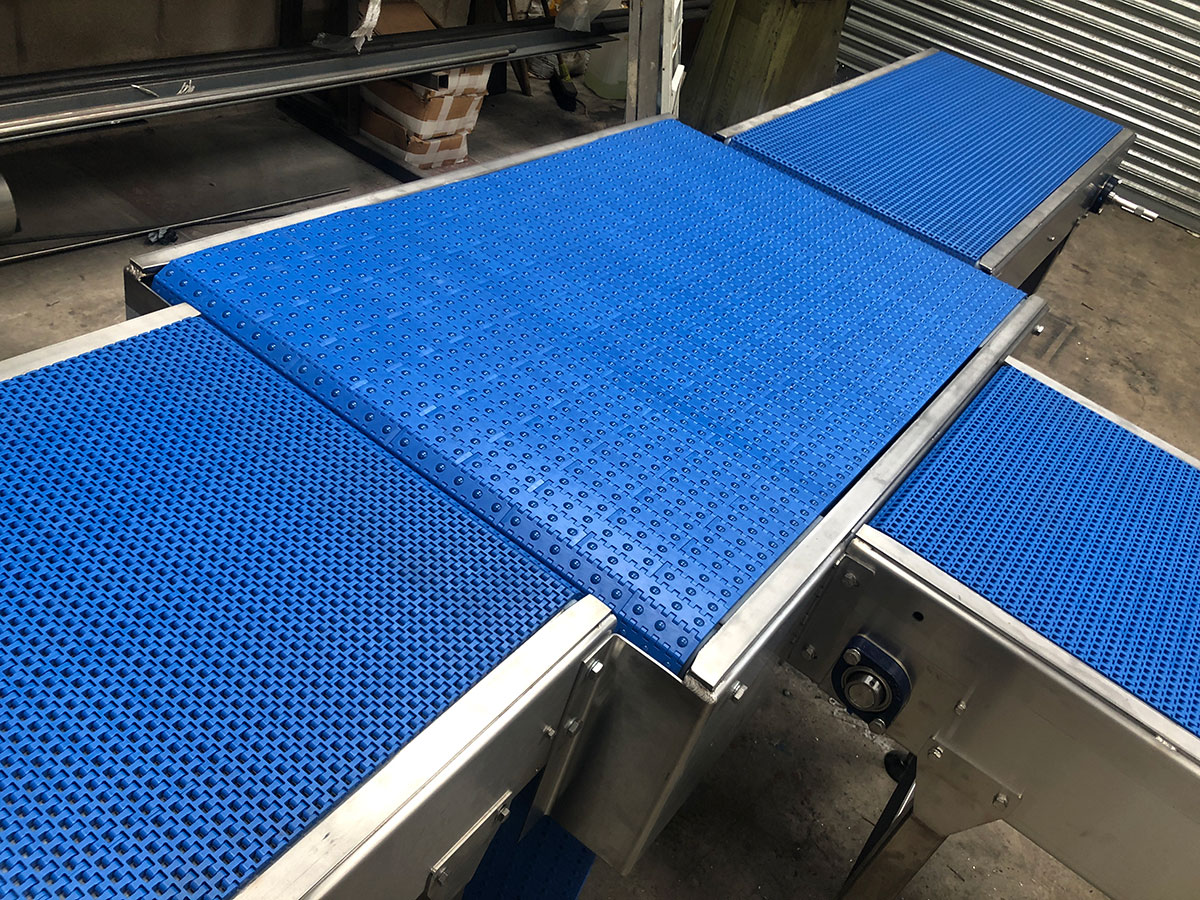

Mechanical Engineering services provided by Singleton range from refurbishment of existing mechanical equipment to the installation of new plant and machinery on site. Typically this involves upgrading or designing new conveyors, picking plates, packaging machinery, foiling units or general process machinery.

Singleton will manage the full scale of mechanical works, co-ordinating all contractors including any electrical, mechanical and software programming subcontractors, to ensure a single point of contact for each commission.

A full project plan is produced with a critical path and regularly updated with progress reports to ensure all parties are kept informed. We’ll guide you through advancements made and raise any issues that may arise, along with suggested solutions to maintain project progress and outcomes.

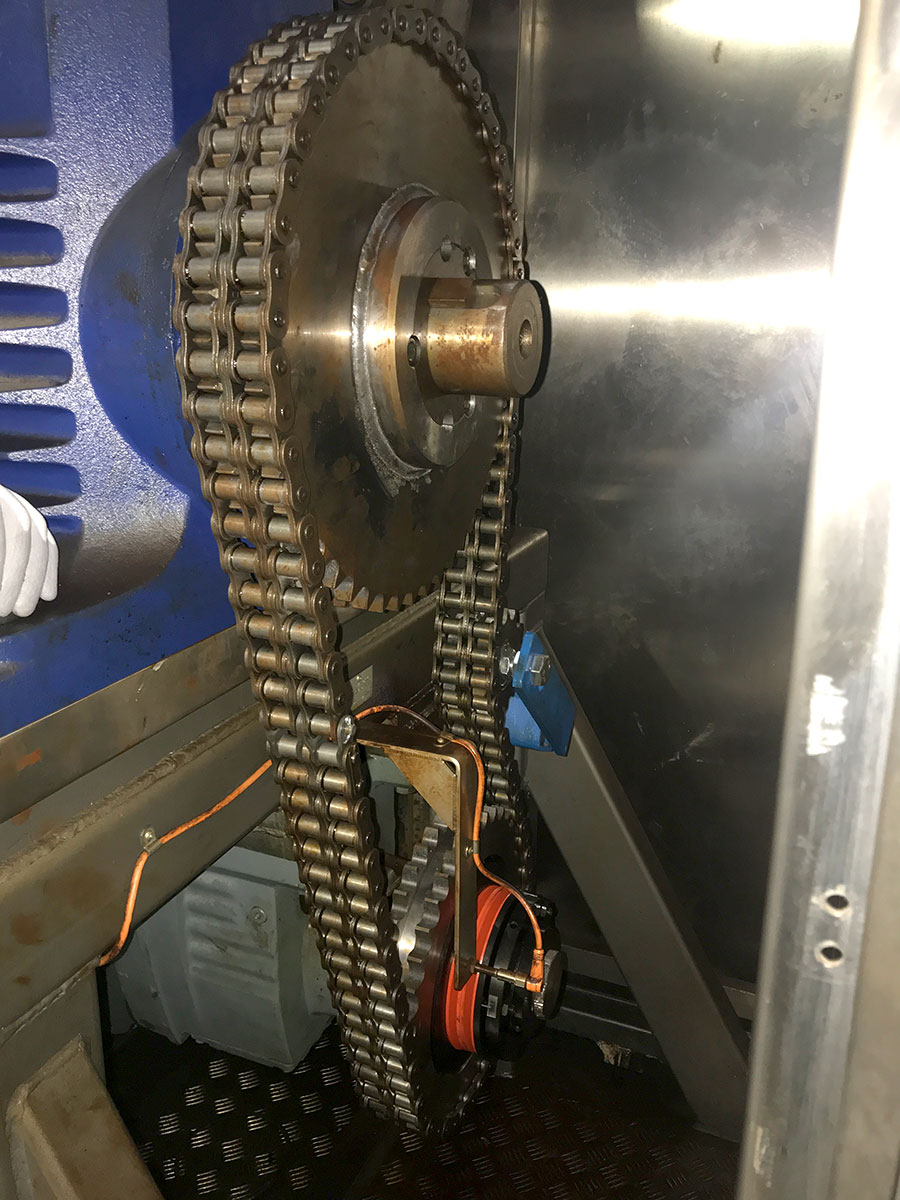

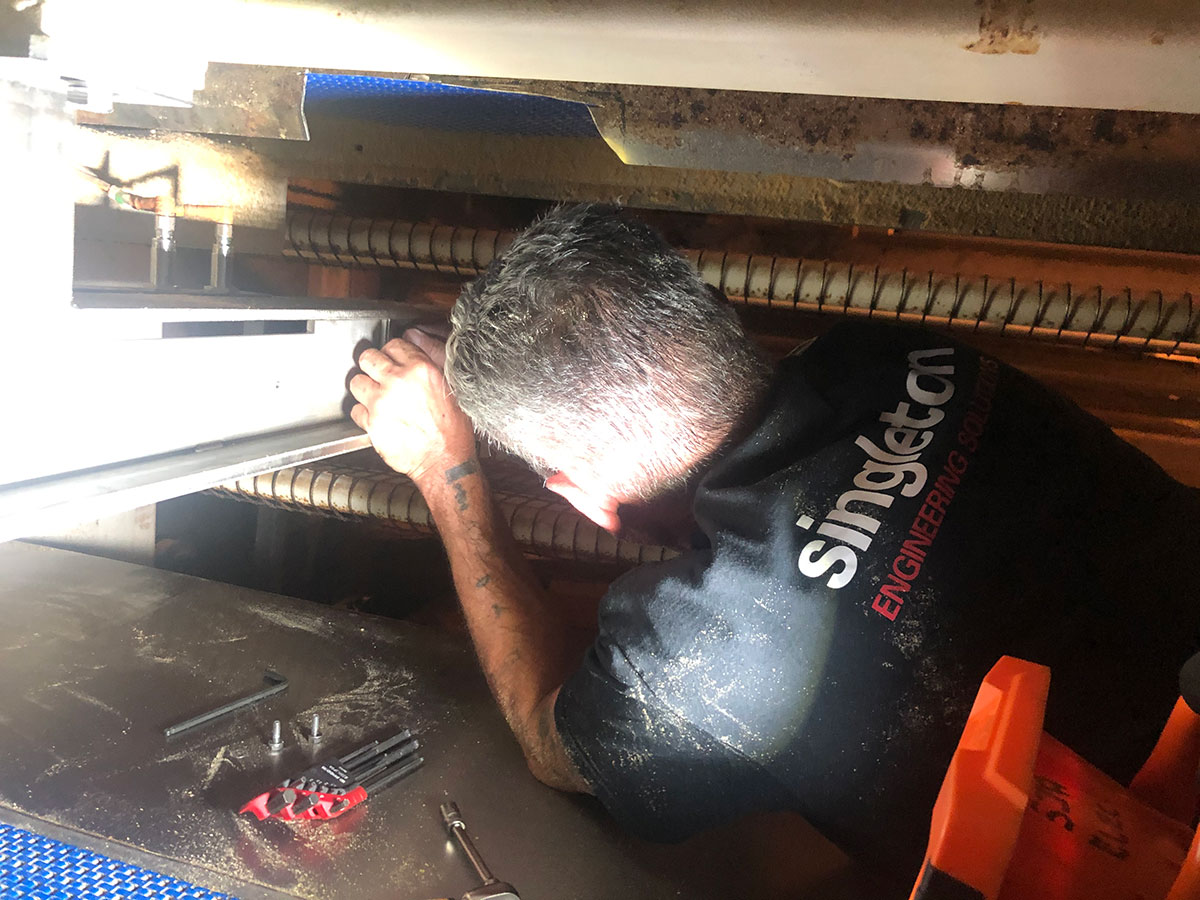

For refurbishment works in particular, our approach often involves completely reconfiguring orientation of the control of the head unit or applicator. Likewise, upgrades often involve adding a bigger motor and diameter shaft to help increase the power and speed of the machine, ensuring improved efficiency.

For refurbishment or new installation projects, Singleton focus on understanding how your processes work and how our mechanical engineering experience can add value and improve the efficiency for your business.