Design and Installation

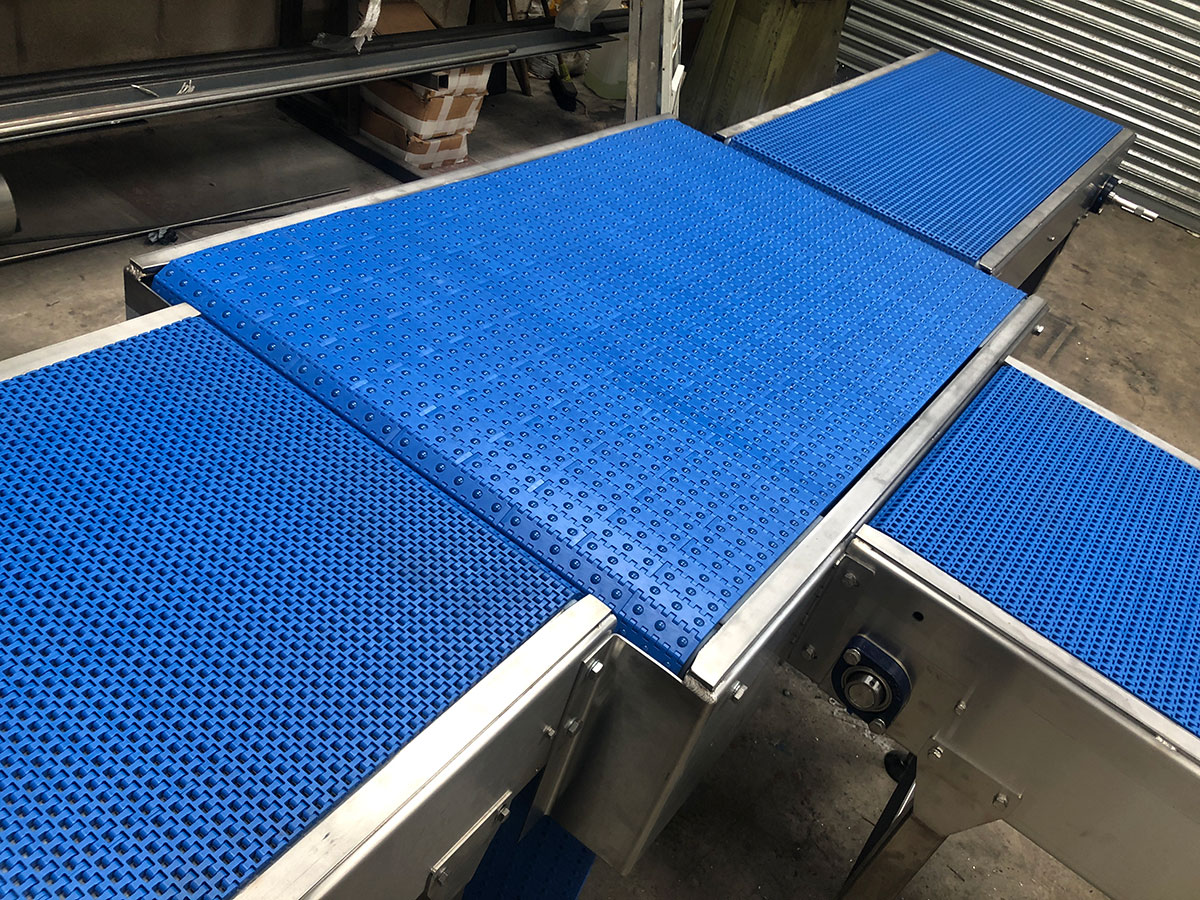

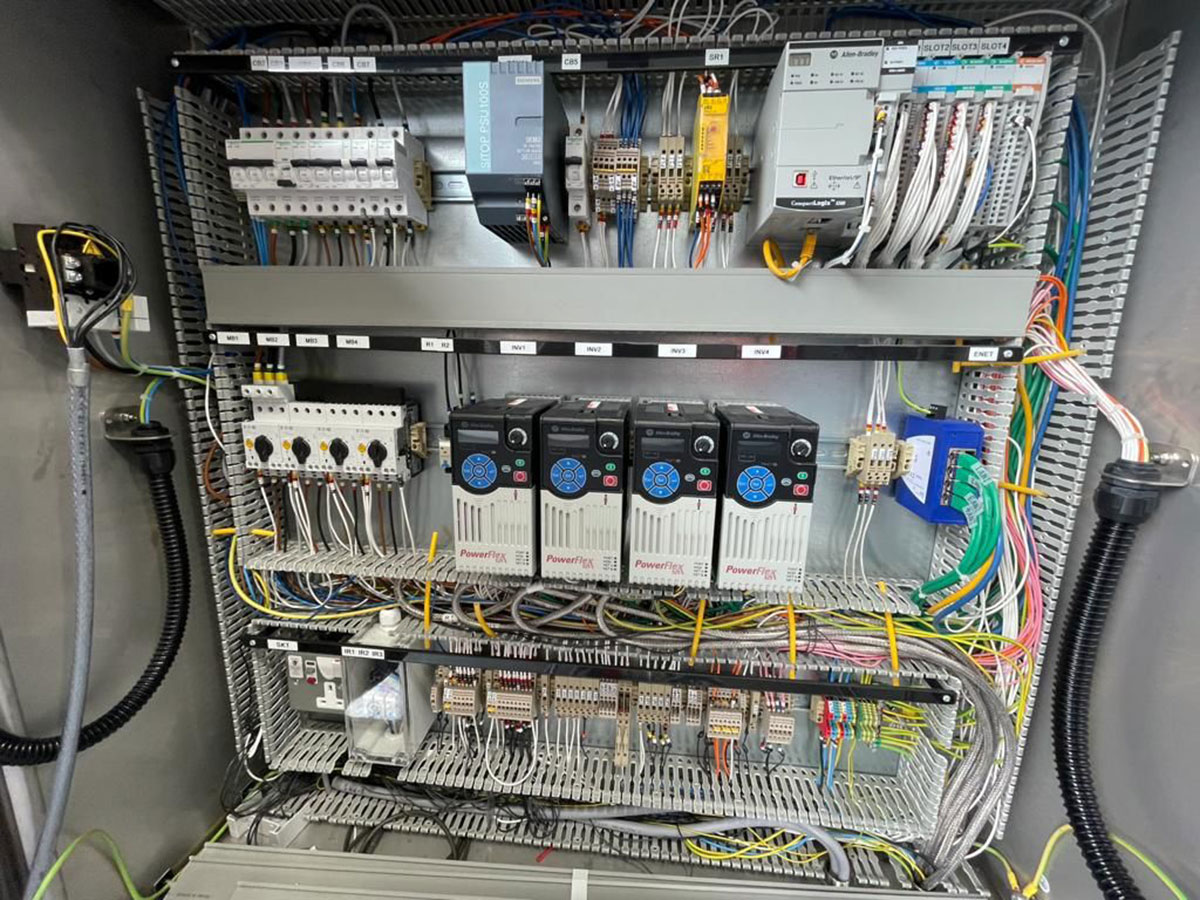

Our design and installation projects involve creating a range of bespoke solutions including staircases, loading machinery, automated conveyer systems, waste strippers, material/product handling systems and control systems.

The process begins with a consultation and site visit to fully assess and understand your requirements and business needs. A design sketch and 3D model are then produced using advanced technology to show you how your design will look prior to development and installation.

Singleton specialise in providing tailored, site-specific solutions to timescale and budgetary requirements, through an efficient and professional approach. Materials used are of the highest quality, and our attention to detail and exceptional craftsmanship will deliver a solution that enhances your business operations.

Project Management

Singleton Engineering provide full project management, liaising with all relevant stakeholders and partners, to ensure delivery of requirements on time and to brief.

Our project management service includes full control of Health and Safety including collating all documentation from the Health and Safety team, collecting the Construction Design and Management (CDM) file, identifying site access and egress requirements and collating the infrastructure of the site from the CDM Manager.

Project management services also include producing a full schedule of works including design, procurement, manufacture, Factory Acceptance Tests (FATs), start on site, installation, milestones, installation over duration and commission testing, with a full handover at the end of the project.

Our role as project manager will encompass ensuring that all required compliance documentation is in place, checking methods are safe prior to work commencing, reviewing welfare facilities and managing the full site. Clients are informed throughout with meetings twice per day to revisit the schedule and assess any issues that have arisen.

Singleton Engineering always raise any concerns at the earliest opportunity and suggest solutions so that the project can continue to run smoothly. We offer guidance at every stage of the process to ensure the project is completed to a high standard and within the set timeframe.

Our previous expertise includes project management of multi-million pound projects a number of the largest contractors across the UK.

Onsite Support

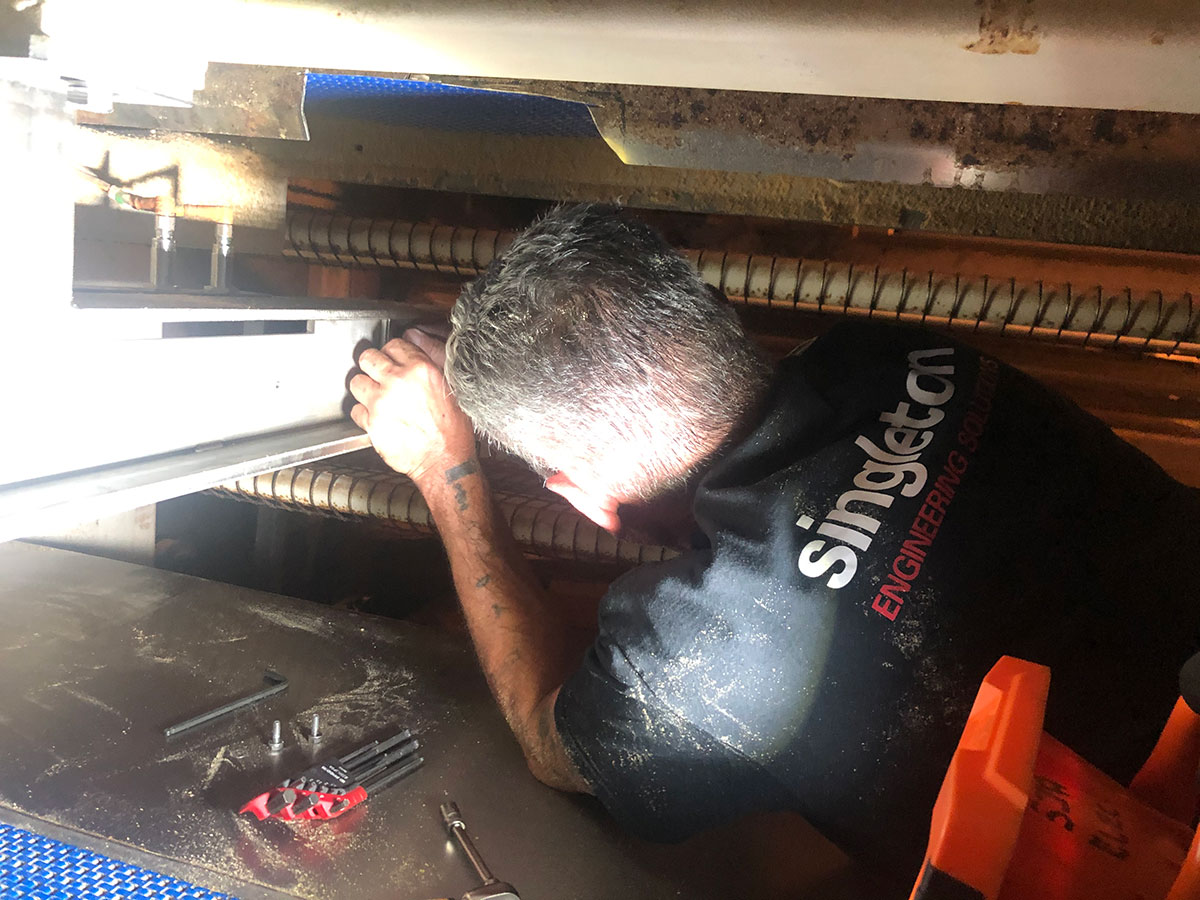

Onsite support can be reactive or planned. Singleton Engineering visit sites to undertake planned maintenance work or carry out emergency repairs to ensure continued operation of a production line.

Our services include repair and maintenance of a range of machinery across a variety of sectors, including proving ovens, coolers, conveyers, extrusion machines, haul offs, packaging machines, bagging machines, hoppers, high tips and mixers.

Our emergency call out service provides a quick and professional response to urgent faults, 24 hours a day, 7 days a week, 365 days of the year. Our team respond to requests as quickly as possible to repair the machinery safely and ensure downtime is as minimal as possible.

We are trusted by our customers to provide effective, prompt onsite support. Our experienced team understand the potential operational and commercial implications of disruption to a production and packaging line and will work in a flexible, efficient manner to resume operations as quickly as possible.

Singleton engineers are available for site-based assignments on a short, medium and long-term basis depending on project specific requirements.

Health and Safety Management

Singleton Engineering offer experience and expertise in managing health and safety on varying scales of engineering projects, from simpler solutions such as repairing access stairs to more complex tasks like stripping a live conveyer.

We work closely with our certified health and safety partners who have over 20 years’ expertise to establish a suitable and compliant safety pack for each project. This involves assessing the risks, outlining the method statement, risk assessment documentation and controls, including required protection for the team involved. The controls suggested help to avoid risks and ensure compliance to health and safety guidelines.

Our in-house team have extensive experience in health and safety management of projects involving large teams on multi-million pound contracts. Team members also hold the appropriate certifications:

- IOSH qualification

- PRINCE2 qualification

- Site Management Safety Training Scheme (SMSTS)

- Full team hold relevant NVQs with health and safety training

Working alongside our certified partners, our comprehensive, experienced and documented approach ensures engineering projects are carried out in a safe and compliant manner.