In food-grade manufacturing, hygiene isn’t optional. It drives every design choice and every piece of equipment used in production. Whether the setting is a commercial kitchen, a bottling facility, or a large processing plant, the materials chosen must support strict health regulations. This is why stainless steel fabrication sits at the heart of safe and efficient food manufacturing. Stainless steel is durable, simple to clean, and highly resistant to corrosion, which makes it ideal for environments with constant washdowns and strict audit demands.

The benefits go beyond using stainless steel. The real difference comes from how well it is fabricated. Precision metalwork ensures the material performs as intended and continues to meet hygiene standards throughout its lifecycle.

The Role of Stainless Steel in the Food Industry

Stainless steel has been the leading material for food production for decades. Its properties align perfectly with the demands of clean and reliable food processing. It doesn’t harbour bacteria, its surface is non-porous, and it resists moisture and odours. It also withstands repeated exposure to strong chemicals and high temperatures.

Food manufacturers in sectors such as meat, dairy, baked goods, ready meals, and beverages depend heavily on stainless steel fabrication. They use it for conveyors, preparation tables, tanks, hoppers, pipework, barriers, and machine components.

Its compatibility with clean-in-place (CIP) systems gives it a further advantage. Stainless steel components can be cleaned thoroughly with minimal downtime, helping production stay consistent and compliant.

Sheet Metal Fabrication in Food Manufacturing

Many food-grade products start with sheet metal fabrication. Through cutting, folding and welding, fabricators create trays, housings, guards, splashbacks and panels that stand up to daily use.

Thinner materials often provide the needed strength without adding unnecessary weight, and grades such as 304 and 316 are chosen carefully based on the operating environment. Components exposed to acidic foods or harsh cleaning chemicals may require 316 for added protection.

Singleton Engineering uses precise sheet metal techniques to build equipment for fast-paced factories where downtime causes real financial loss. Whether the project involves hygienic workstations or custom covers for machinery, the goal remains the same: a clean, efficient and long-lasting solution.

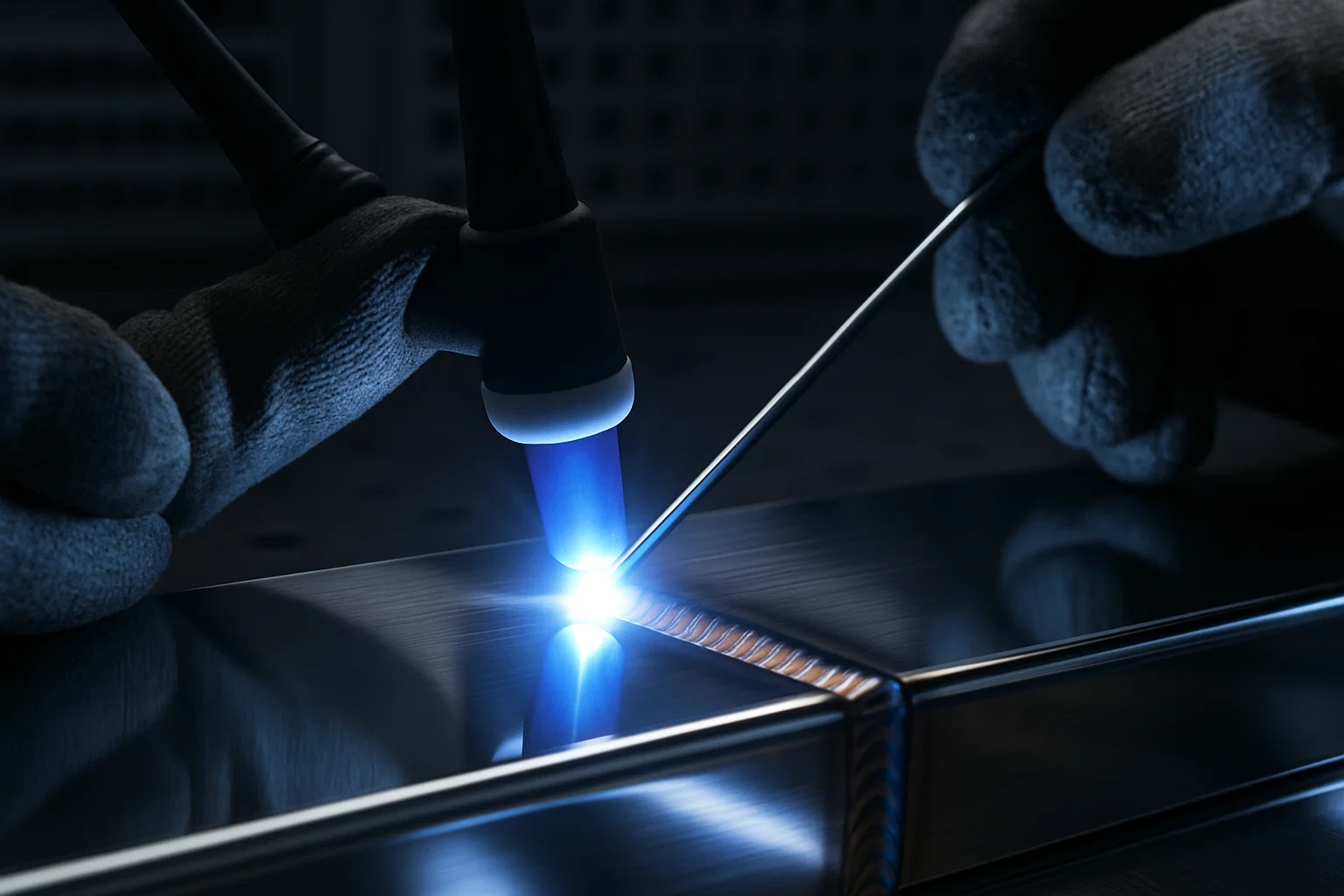

Welding Techniques That Stand Up to Inspection

In food environments, the quality of a weld can determine whether equipment passes inspection. A poorly executed weld can trap debris, allow bacteria to grow, or weaken over time. This is why choosing the right welding technique matters.

Singleton Engineering uses both TIG and MIG welding to suit different applications. TIG welding is ideal for fine, smooth welds that require polishing. MIG welding supports structural pieces that need strength and reliability. Spot welding is sometimes used for lightweight components where speed and accuracy are essential.

By understanding each technique in detail, fabricators can select the method that delivers strong, hygienic, and consistent welds across all equipment.

Pipework and Structural Frames for the Food Sector

Pipework is one of the most frequent requests in food-grade manufacturing. It must withstand high pressure, intense cleaning routines and contact with temperature-sensitive products. Facilities producing dairy, beverages and flavours often rely on 316 stainless because of its superior corrosion resistance.

Fabricators also build the structural frames that support conveyors, tanks and machines. These frames must take constant stress, regular washdowns and heat without losing integrity or becoming unsafe.

Where components do not contact food, carbon or mild steel may be used, but stainless steel remains the top choice for all hygiene-critical areas.

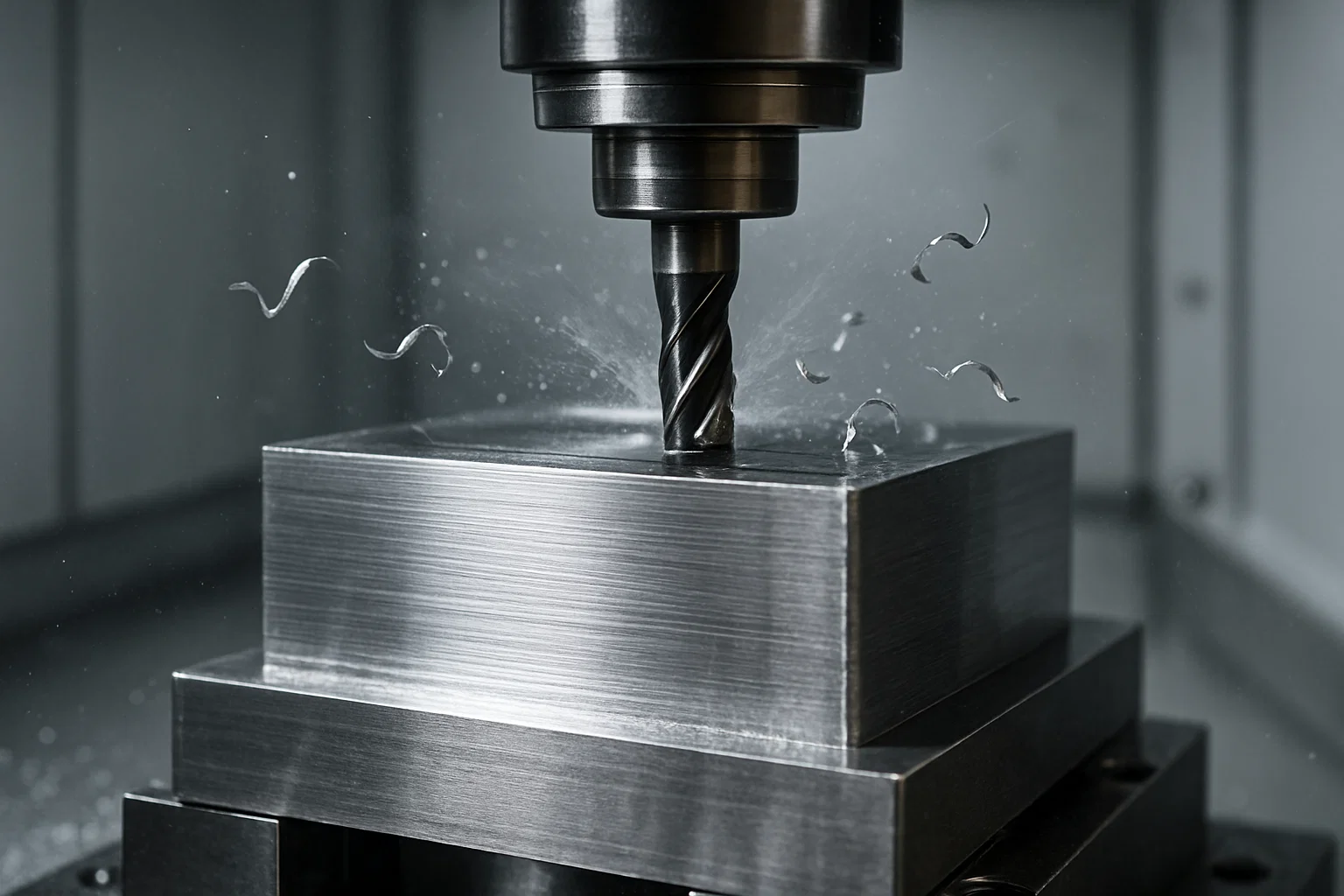

CNC Precision for Complex Components

Modern food facilities often contain automated systems, sensors and integrated lines that require CNC-machined components. Accuracy down to fractions of a millimetre keeps machines running smoothly and reduces the risk of mechanical failures.

Singleton Engineering uses CNC mills and routers to create brackets, control panels, mounts and custom fittings. These parts help manufacturers avoid compatibility problems that often come with standard, off-the-shelf components.

The ability to machine parts to exact specifications is a key reason food manufacturers view their fabricator as a long-term partner rather than a one-off supplier.

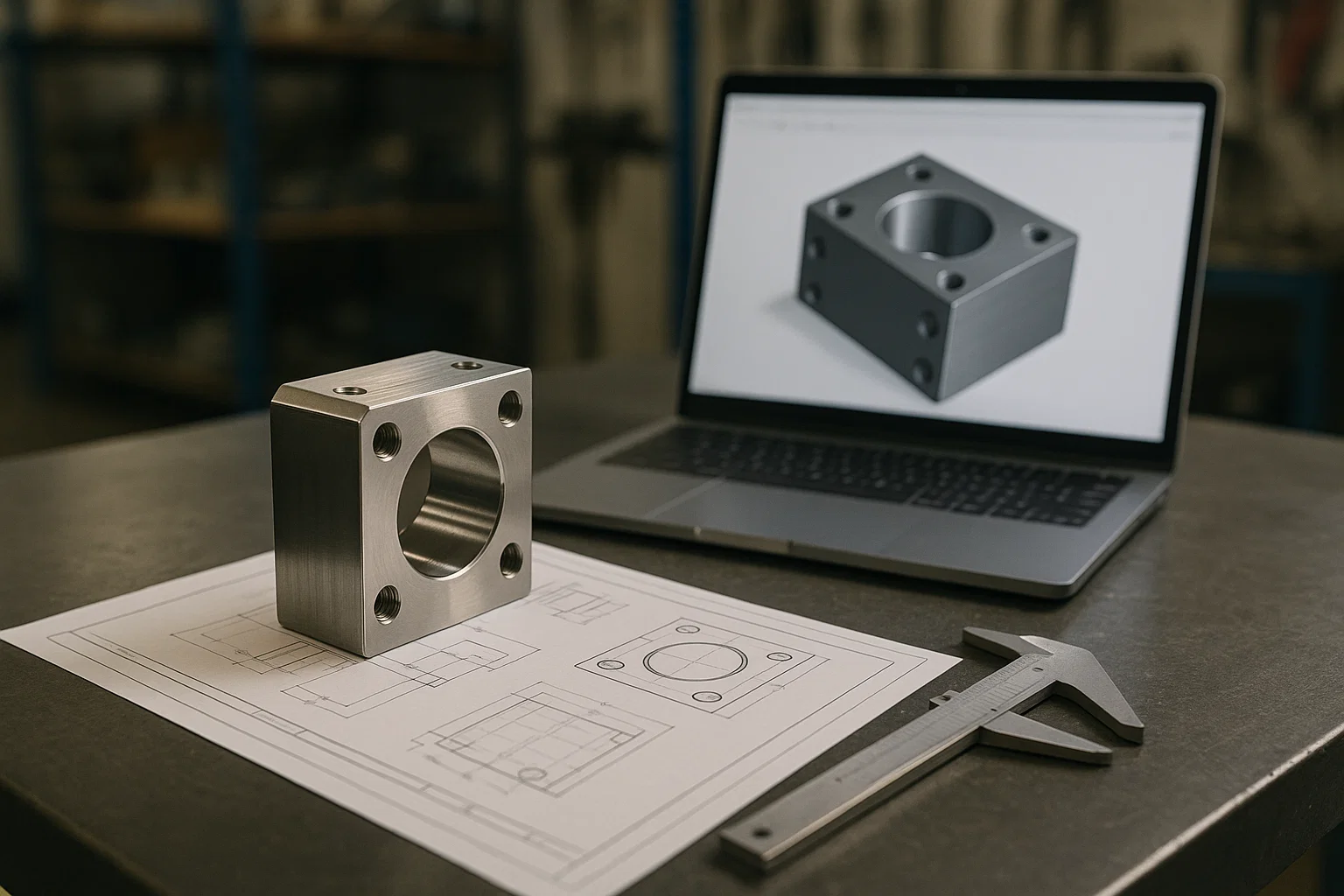

Managing Fabrication Projects from Concept to Completion

Food factories often work to tight timelines. A single delay during installation or maintenance can cost thousands in lost production. This makes effective project management essential.

Singleton Engineering takes projects from the initial survey through to fabrication and installation. Every part is delivered ready to perform, with full traceability and documentation to support audits and compliance checks.

This focus on reliability and communication is why many of the UK’s leading food manufacturers return for repeat work.

Real-World Applications Across the UK Food Industry

Food-grade stainless steel fabrication supports a wide range of environments. Here are some examples from real-world installations across the UK:

Dairies: Stainless steel milk tanks that are polished and sealed to maintain freshness.

Commercial bakeries: Heat-resistant sheet metal racks and oven covers with smooth, seamless welds.

Meat processing: Durable frames and barriers that eliminate contamination risks.

Beverage facilities: Custom mixing tanks with CIP-ready pipework, safe access points and service panels.

Each project is built with hygiene, flow efficiency, safety and space optimisation in mind.

A Smarter Material, Fabricated for Performance

Stainless steel offers strength, hygiene and durability in demanding production environments. In food-grade manufacturing, it enables fast cleaning routines, long service life and consistent safety standards.

Still, the material alone isn’t enough. Well-designed equipment, precise fabrication and industry-specific experience ensure stainless steel performs at its best.

From the first sketch to installation day, Singleton Engineering provides stainless steel solutions that meet regulations, improve performance and keep production running.

Ready to discuss a new project? Get in touch with Singleton Engineering Solutions for stainless steel fabrication built for the food sector.