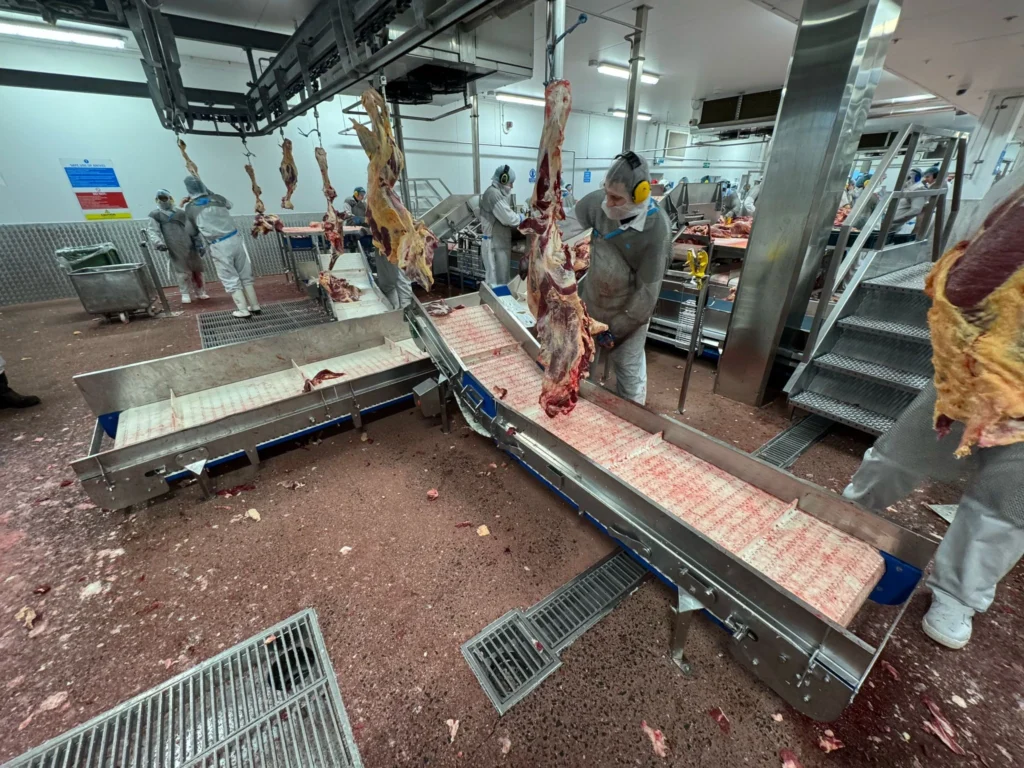

Smart Engineering for Demanding Food Production Environments.

Singleton Engineering Solutions delivers custom-built machinery, responsive maintenance, and precision fabrication for food production and processing facilities across the UK. Our team has extensive experience working in live food environments, with an in-depth understanding of hygiene standards, compliance requirements and operational pressures.

We regularly support one of the UK’s largest bakery manufacturers, helping them optimise uptime, improve throughput and maintain strict food safety standards.

We manufacture tailored equipment to support every stage of food production, from oven unloaders and tin cleaners to stainless steel blowers and bespoke conveyors. Each machine is built with durability, washdown compliance and efficiency in mind.

When your facility is running around the clock, reliability matters. That’s why our engineering work is always geared towards long-term performance with minimal disruption. We’re used to operating during short maintenance windows or planned shutdowns, delivering solutions that integrate smoothly into your production flow.

Our team provides both reactive support and planned inspection services. Whether you’re looking to extend the life of existing assets or reduce your reliance on emergency callouts, we’ll help you take control of your equipment strategy.

We’ve recently worked with a nationally recognised bakery brand to implement a full preventative maintenance plan across their provers, coolers and ovens. The result? Fewer breakdowns, more predictable servicing and lower annual repair costs.

With trained engineers who understand the intricacies of temperature control, moisture, debris build-up and fast-moving equipment, you can trust us to catch the small issues before they become production-stopping failures.

From the moment we arrive on site, our team works to food-industry standards. We bring dedicated food-safe toolboxes, wear correct PPE and carry out every job with cleanliness and cross-contamination prevention in mind.

We’re not just fabrication experts, we’re specialists in engineering for food environments. That means every weld, every bracket and every panel is designed for easy cleaning, safe handling and reliable use.

We also support manufacturers with shift cover during staff shortages, providing skilled mechanical and electrical engineers who can step in, troubleshoot and keep things moving.

Singleton Engineering Solutions design, fabricate, install, and maintain bespoke machinery, steelwork and engineered systems for manufacturers, food producers, and industrial firms across the UK.

Copyright © 2025 Singleton Engineering Solutions.

Site managed by Rank Kings