Computer Numerical Control (CNC) machines have revolutionised the way products are designed, manufactured, and fabricated across various industries, including construction, consumer goods, and aerospace engineering. These technologies combine advanced machinery, high-powered tools, and sophisticated software to produce results that manual or semi-automatic fabrication simply cannot match.

CNC cutting technologies can cut, shape, and machine components from a wide variety of materials, including metals, plastics, fiberglass, foam, and composites. Each of these machines delivers components precisely cut and shaped to specification with remarkable repeatability. It is this repeatable precision that has rendered CNC technologies indispensable in industries that require tight tolerances and high-quality components.

In this blog, we’ll explore the world of CNC profiling to understand what it is, how it works, and why it has become an essential part of modern fabrication.

Efficient, Repeatable Precision

In today’s assembly plants, where tight tolerances are the order of the day, a small deviation from specification can mean the difference between a quality assembly and high-volume scrap. It is a fact that few modern fabrication plants could survive without the efficiency and precision provided by CNC profiling.

Steel and stainless steel are among the many materials processed through CNC machines, forming the backbone of hundreds of applications from automobiles to appliances. Steel is strong, versatile, malleable and durable, but it is tough to work with unless you have a CNC machine.

What is CNC Profiling?

CNC profiling is the process of cutting, shaping, and machining materials using automated tools controlled by computer-aided design (CAD) software. The “profiling” aspect refers to the way a CNC machine can follow an exact programmed path to create precise cuts and contours rather than relying on manual skills. The result is repeatable cuts, smooth edges, and dimensionally accurate components time after time.

CNC profiling eliminates the risk of human error, as it relies on digital designs and precise machine control. The software-designed component can be converted into machine code, which tells the CNC machine how to move, cut, and process the material.

Profiling provides manufacturers with the confidence that steel CNC cutting will produce consistent and accurate components. This technology can fulfil the need for thousands of identical parts used in large-scale production. It is equally accurate when making a single component.

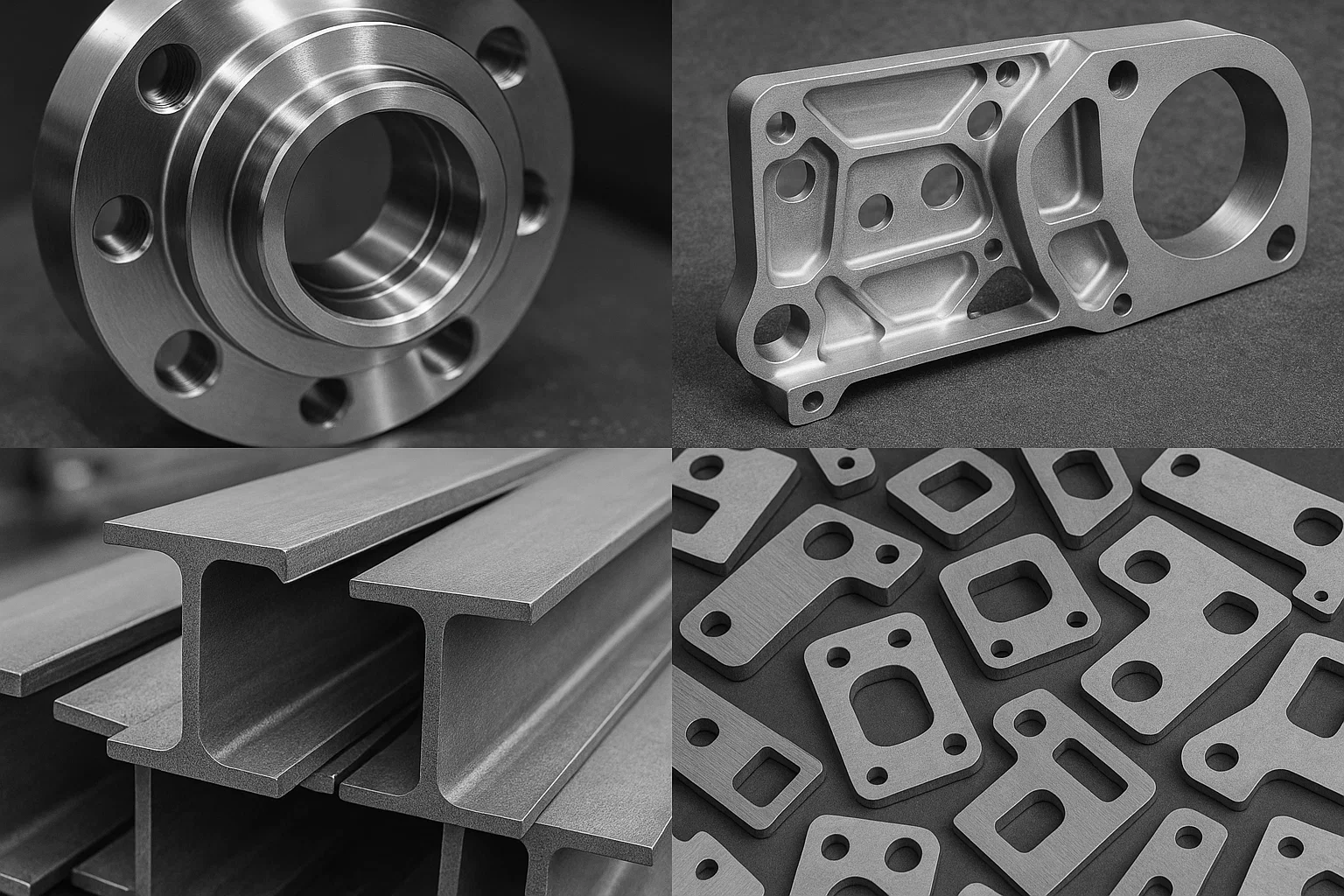

So, if you’re asking, “Can a CNC machine cut metal?” the answer is a resounding yes; it can cut steel exceptionally well. Profiling tables are particularly adept at handling mild steel, stainless steel, and aluminium of various gauges. From small brackets to heavy-duty baseplates and components with complex geometries, CNC profiling offers a clean and consistent solution.

Why Steel and Stainless Steel?

Steel is the material of choice in engineering, manufacturing, and construction due to its strength, plasticity, and versatility. Stainless steel is highly corrosion-resistant, and thanks to its polished finish, it is the preferred choice for industries requiring hygienic surfaces, such as the medical device, pharmaceutical, and food processing sectors.

Still, working with steel can be tricky. The material is more rigid, denser, and more resistant than softer metals like aluminium or brass. Cutting steel with manual tools is slow, inaccurate and can damage the material.

It is because of this that CNC steel machining has become so valuable. CNC machines are accurate and efficient. They offer software-driven precision and advanced tooling, from CNC machining of stainless steel components in the aerospace industry to CNC cutting of mild steel sheets in construction. These machines ensure that components are precisely cut and shaped to your specifications. It is a process you can depend on.

How CNC Profiling Works

The CNC process is quick and straightforward, consisting of four stages:

- Design: Designers create the part using CAD software. A skilled draftsman can generate a component drawing from a sample or even a hand sketch. A drawing is supplied to the machine as a DXF or DWG file.

- Programming: The file is converted into machine code (G-code), which instructs the CNC laser or mill how to move and cut.

- Cutting: The machine cuts the steel precisely according to the code.

- Quality Control – Each batch is inspected to ensure dimensions to specification and clean burr-free edges and finishes.

The CNC profiling software and hardware work in harmony to create reliable, repeatable components.

CNC Machine Types for Steel

CNC machines should be carefully chosen based on the process. Consider the material thickness, design complexity, and intended end-use when selecting the most suitable machine for your application. There are several machines that may suit your process.

A CNC Milling Machine for Steel

A CNC steel mill uses rotating cutting tools to remove material from a steel block. It can create highly detailed components and is ideal for complex geometries, holes, and surface finishes. These machines feature advanced spindles, tooling, and coolant systems, capable of handling stainless and mild steel.

CNC Routers for Steel

CNC routers are commonly used for wood and softer materials, and they are generally not suitable for cutting harder materials like steel. Yet, modern CNC router steel cutting systems have stronger spindles and reinforced frames to handle light to medium-duty metal cutting. Ensure that you have the appropriate feeds, speeds, and tooling to cut steel on a CNC router. Shops that handle multiple materials may find these CNC router systems helpful.

CNC Laser Cutting Machines for Steel

A CNC laser cutting machine for steel is unmatched in its capabilities when working with thin sheets with intricate designs. The laser beam’s intense heat melts the steel, while assist gases blow the molten material away. The result is clean, burr-free edges of incredible precision. CNC laser cutting machines for sheet metal can produce a wide range of products, including enclosures and decorative panels.

Desktop CNC Steel Machines

Many businesses do not have the output to justify an investment in an industrial-sized CNC machine. Desktop CNC mills are well-suited for steel work, particularly in prototyping or small-scale projects. These machines offer a compact and affordable solution for small to medium-sized engineering, design, or production facilities. Although they don’t have the power of full-scale machines, desktop CNC mills are an excellent choice for machining small CNC stainless steel parts and light-duty, mild steel parts.

CNC Steel Cutting Applications

For many industries, CNC profiling has become an indispensable process. Some of the key sectors relying on CNC steel machining are listed below:

- Automotive Components: Precision CNC steel parts create essential safety-critical engine, transmission and body components.

- Aerospace: CNC stainless steel machining services produce high-strength components to withstand extreme temperatures and weather conditions.

- Construction: Structural beams, brackets, and plates are often formed on CNC sheet metal cutting machines.

- Medical: Surgical tools and implants rely on stainless steel CNC cutting for precision and safety.

- Consumer Goods: Appliances, electronic equipment, and even furniture often require custom CNC metal cuttings.

Wherever they are used, CNC proofing provides efficient reliability and consistent quality.

CNC Steel Profiling Advantages

Why is CNC profiling viewed as the backbone of fabrication? The benefits speak for themselves. With CNC profiling, you can expect:

Cutting Integrity: CNC steel cutting machines can provide tight tolerances, not possible with manual cutting.

Repeatable Quality: Once programmed, the machine can produce thousands of identical components.

Production Efficiency: Automated processes reduce time and labour and can produce high volumes in a remarkably small amount of time.

Flexibility – CNC machines produce an endless array of possibilities, from thin sheets off a CNC laser metal cutting machine to thick steel blocks cut on a CNC steel milling machine.

Cost Savings: CNC machines produce less waste, and automation reduces errors and labour input.

Scalability: From prototype to samples and mass production, CNC machines adapt well to any situation.

CNC Machining Steel Challenges

CNC machining is not all plain sailing, and you will face a few challenges, including:

· Tool Wear: Steel quickly dulls tools, which will require frequent replacement. It is a good idea to have spares in stock, along with a documented maintenance program. Regular batch checking will ensure that the machines continue to produce high-quality, burr-free edges.

· Heat Buildup: Friction creates heat that can damage parts and tools if not managed. To reduce the heat, reduce the spindle speed and feed rate. CNC machine maintenance is an essential element, ensuring that loose debris does not interfere with the tools. The appropriate tool choice, in terms of geometry, flute count, and size, can contribute to or reduce heat buildup.

· Machine Rigidity: If you plan to cut hard materials, you will need a sturdy machine frame that does not vibrate.

· Programming Complexity: The more complex the designs, the higher the skill requirement for programming and simulation.

Businesses that prefer not to deal with the challenges of CNC profiling often seek professional CNC metal cutting services rather than producing the components themselves. Professional CNC service providers have the experience, equipment, and optimized workflows to ensure efficient production output.

The Rise of CNC Metal Cutting Services

For small and medium-sized businesses, production requirements may not justify an investment in a CNC metal cutting machine. In these cases, it may be more efficient to outsource your requirements to specialists. Professional CNC metal cutting services or stainless steel CNC machining services can offer the following:

Advanced equipment like laser CNC metal cutting machines or high-speed mills.

Experienced machinists who understand material properties and programming.

Faster turnaround times and lower upfront costs.

Scalable solutions for or one-off parts and mass production runs.

Outsourcing custom CNC metal cutting enables you to focus on design, sales, and distribution, while leaving the technical fabrication to experts.

CNC Steel Profiling: The Future

Like all modern technologies, CNC profiling is continually evolving. Innovations ensure that this technology is becoming increasingly powerful and accessible to an ever-growing number of businesses. However, growing market pressures and globalization will continue to drive companies to seek more competitive advantages, and CNC profiling is among the technologies that are driving 21st-century manufacturing progress. Here is what you can expect in the next few years:

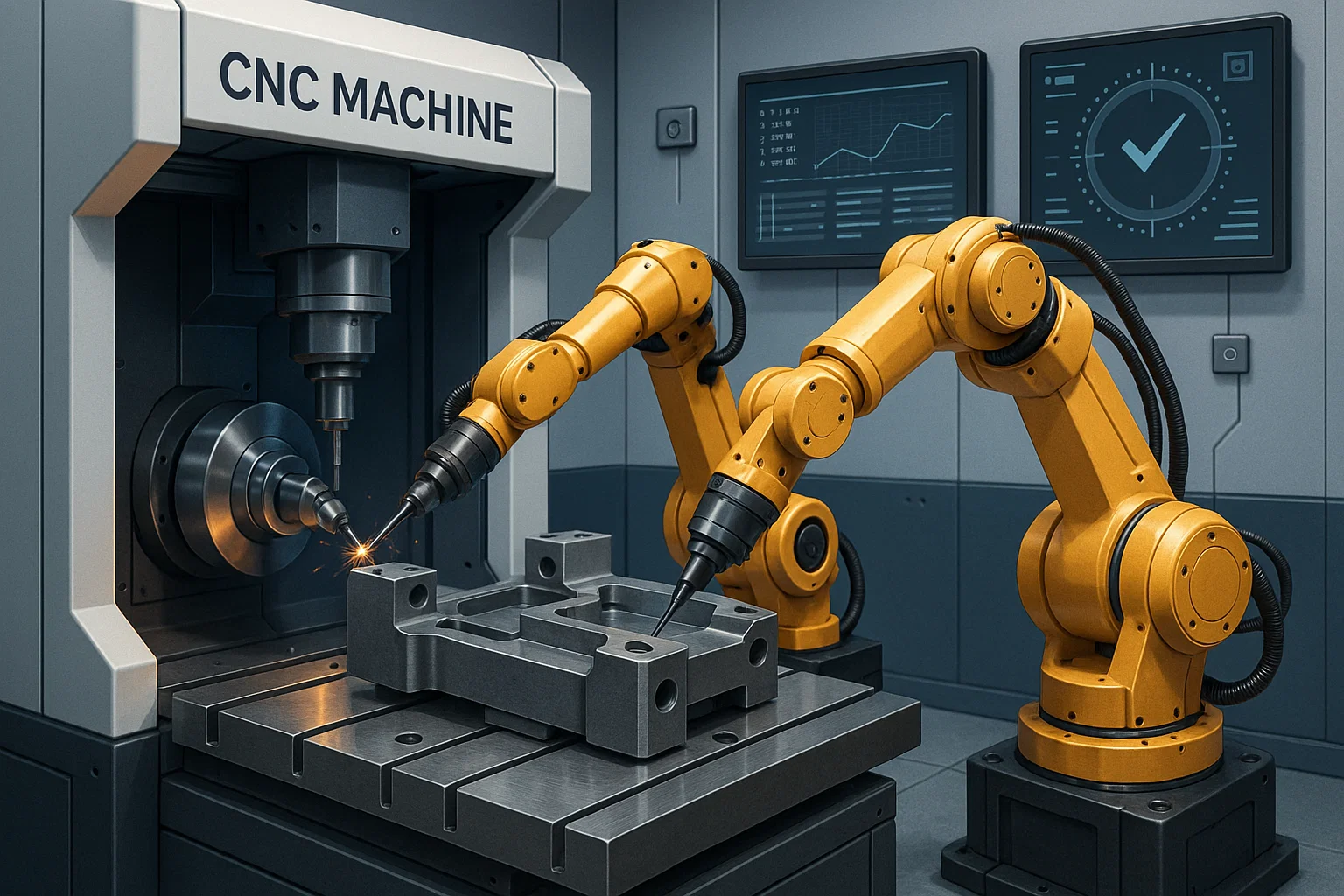

Automation and Robotics: Machines will become increasingly more integrated and automated. Already, robotic arms have become the norm for handling and assembly, driving higher productivity and reducing waste.

AI and Smart Machining: Adaptive systems adjust feeds and speeds as and when needed to improve efficiency.

Hybrid Machines: Combine milling, laser cutting, and even 3D printing into one setup.

Waste Reduction: Modern CNC steel cutting machines minimize waste and optimise energy use by design.

CNC profiling is destined to remain at the centre of fabrication for the foreseeable future.

CNC Profiling Leads the Way

This leads the way in cutting, shaping, and working with steel across a wide range of industries. From CNC laser steel cutting machines for delicate sheet metal to heavy-duty CNC steel mills for industrial parts, this technology delivers precision, efficiency, and scalability as never before.

CNC machines cut and work steel with unmatched accuracy, delivering a repeatable consistency you won’t find in just any Press Shop. Consistent quality and high speed, efficient component delivery ensure that CNC profiling remains the backbone of modern fabrication, whether you’re considering an investment in a desktop CNC mill for steel or looking for CNC stainless steel machining services.

In a global market where quality, speed, and cost containment are more important than ever, CNC profiling stands as the ultimate tool for transforming raw steel into the components that build our cars, power our machines, advance medical technology, and shape the structures around us.