The food processing machinery industry faces many challenges, from hostile environments to stringent health regulations. The sector also operates in a highly competitive market, requiring the stringent cost controls that are only possible in highly efficient operational environments. These factors, along with the need to produce a diverse range of products, create an environment where every new project is an opportunity to improve operations.

Bespoke food processing machinery designed and fabricated by the right stainless steel project partner is just such an opportunity. Fully integrated systems built around your layout and process improve efficiencies and ensure easier sanitisation and maintenance.

In this article, we examine why thoughtfully designed, precision-manufactured bespoke machinery can make all the difference in a food processing plant. We then walk you through the process to demonstrate the importance of each step in the machinery’s manufacture.

Why Choose Customised Food Processing Machinery?

A customised machine is the best fit for any factory because it is designed to fit perfectly on your production line. The machine is then integrated with the existing line so that all equipment is synchronised, working harmoniously as one.

This approach works far better than buying catalogue machinery, where you are forced to change your workflow to suit the machine. Custom-built machines should fit directly into your operation. Engineering companies like Singleton Engineering design and build these machines specifically for your product, your layout, and your environmental realities.

Metal Fabrication Tailored to Your Layout and Production Process

Food factories are often short on space. Bespoke machinery can be shaped, sized, or curved to follow the workflow without disrupting existing equipment. The Singleton team can adapt conveyors to slopes or turns, fitting washdown systems into restricted areas. Space can also be saved by stacking multi-stage machines vertically. Instead of redesigning the factory for the machinery, we design the machinery for the factory.

How the Product Affects the Machine Design

It isn’t just the layout that supports the case for customised machinery. The design of a bespoke machine starts with understanding the product that flows through it. Food items have different characteristics that dictate line speed, suitable materials, mechanical features, and surface finish. A well-designed, properly manufactured food processing machine reduces material waste and consistently delivers reliable results for your business.

Stainless Steel Project Management: From Design to Installation

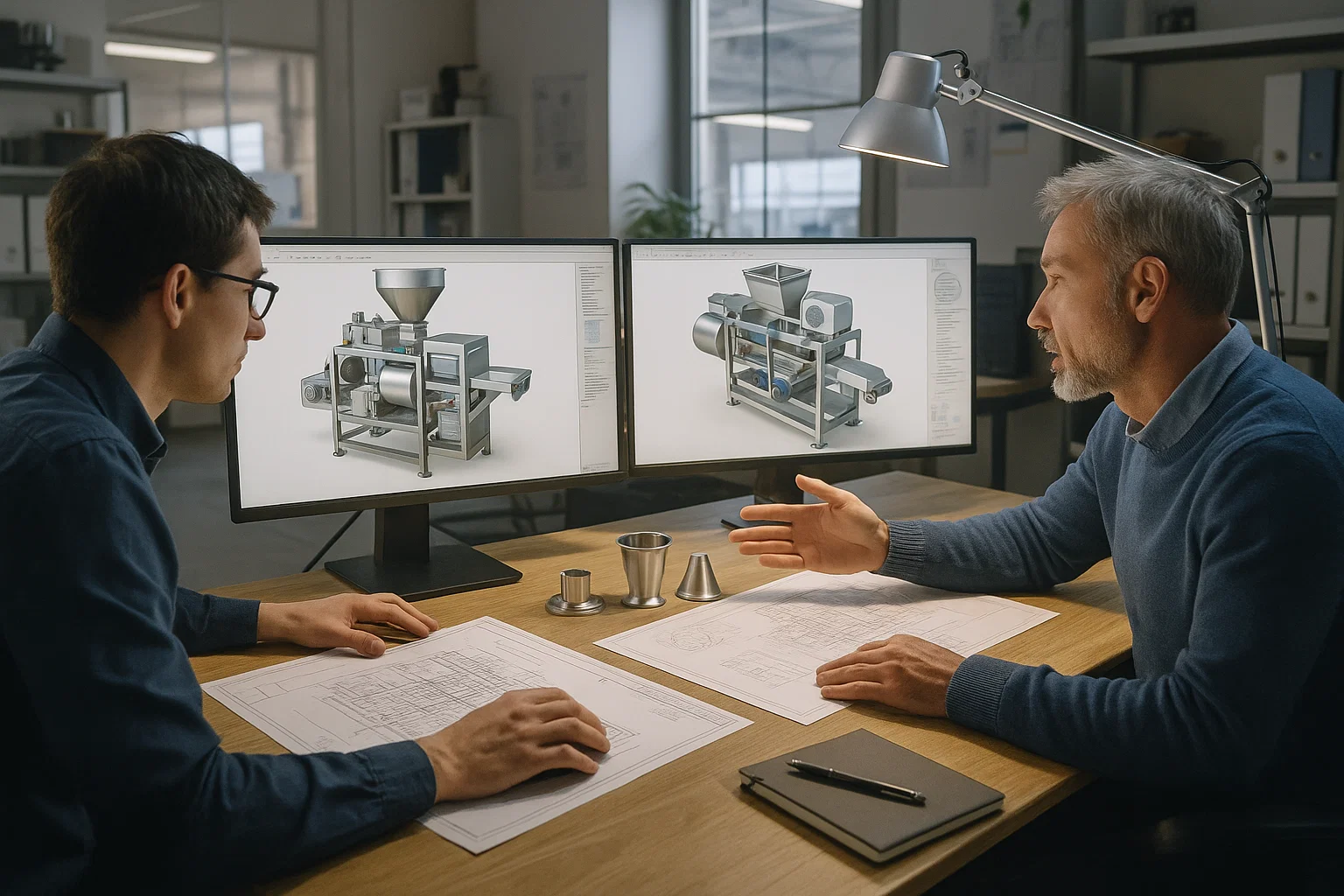

The design phase is where an idea becomes a practical piece of machinery. Here, the designers convert your factory’s requirements into a detailed plan ready for fabrication, testing, and installation. Your goals provide the guidelines, supported by advice from the engineering team.

This is where planning becomes reality. It is essential that the design is precise and considers every aspect of production, cleaning, and maintenance.

A good design begins with a clear understanding of the production process. Engineers will meet with the client to discuss production, map the process, and understand any bottlenecks or hygiene issues.

At this stage, it is important to identify which production improvements should result from the new machinery. Objectives may include improved throughput, greater accuracy, automation, or launching a new product line. A site survey typically follows to allow the engineers to take measurements, assess access points, and understand how new equipment will interact with the existing line.

Translating Requirements Into Detailed Engineering Designs

Machine designers use Computer Aided Design (CAD) software to create detailed models containing all the main components, from frames to motors, conveyors, and washdown equipment. The team tests how products flow along the line and how fluids will drain. They also assess how operators access parts for cleaning and maintenance.

Hygiene is always a priority in food processing. Equipment must be easy to clean and must minimise potential bacteria traps to comply with food safety regulations. Engineers specify smooth surfaces, hygienic welds, and components designed for easy removal.

To support readers on the subject of hygiene requirements, you may refer to the Food Standards Agency’s hygiene and cleaning guidance:

https://www.food.gov.uk/safety-hygiene/cleaning

The design team also focuses on ergonomics and usability. Considerations include ease of maintenance, clear controls, and layouts that minimise manual strain. Control panels, sensors, and safety systems form part of the initial development in automated machinery.

Machine Fabrication and Assembly

Once the design is approved, the machine moves into fabrication. The Singleton Engineering team now transforms digital plans into high-performance stainless steel food-processing machinery. Precision, skill, and quality control combine to create durable equipment capable of daily use.

Material Selection

Fabrication begins with selecting the correct materials. Metallurgists choose stainless steel grades that meet strict food-grade standards and offer durability and corrosion resistance. The factory maintains full material traceability in line with industry regulations.

Why Stainless Steel is the Industry Standard

The food industry demands exceptional hygiene standards. Materials used for processing cannot absorb moisture, harbour bacteria, or react with ingredients. Stainless steel satisfies all these requirements. No alternative material offers the same combination of strength, hygiene, and durability.

Its smooth, non-porous surface makes cleaning and sanitisation far easier. Its corrosion resistance is another major advantage. Equipment in food processing is frequently exposed to water, heat, acids, salts, and cleaning chemicals. Less robust materials will corrode under these conditions, creating hygiene issues or downtime.

For a further deep dive into stainless steel’s importance in food-grade manufacturing, read our article on:

How Stainless Steel Fabrication Supports Food-Grade Manufacturing

CNC Cutting and Profiling: Precision Sheet Metal Fabrication

Highly precise tools, such as CNC laser cutters and profilers, cut and form the metal components. These machines deliver parts to exact specifications, which is essential because even a small error affects performance and alignment on the production line.

Once cut, parts are formed into the required shapes. These become frames, chutes, mechanical components, and more. Skilled welders then create seamless joints with no cracks or creases where moisture or debris can accumulate.

Surface Finishing and Quality Control

Surface finishing creates a smooth, easy-to-clean exterior. Operators polish away imperfections, paying particular attention to surfaces that will be in contact with food.

Quality control checks follow each stage. Operators assess dimensions, welds, and surface finishes to ensure each component meets the design and food-grade standards.

Integrating Automation and Controls

At this point, the machinery begins to come to life. The automation process starts with discussing the appropriate automation level with the client.

Some lines operate with simple, reliable motor control and basic sensors. Others require advanced PLC systems, touchscreen HMIs, robotics, data logging, or integration with factory-wide SCADA networks. The goal is always the same: streamline processes, reduce manual handling, and improve efficiency.

For a real-world example of engineering support in high-demand food production environments, check out our previous article: Bakery Engineering Support That Keeps Production Running 24/7

PLC Systems

PLC (Programmable Logic Controller) systems underpin most modern food-processing machinery. They manage timing, sequencing, and safety protocols. They synchronise conveyors, respond quickly to changes, and allow operators to adjust settings such as speed, temperature, and fill levels.

Sensors and Emergency Stops

Sensors measure product weight, temperature, flow, and pressure. They can trigger adjustments, stop the machine, or notify operators of maintenance needs. This reduces downtime and increases reliability.

Emergency stops, guards, overload protection, and fail-safe shutdown systems ensure machinery complies with UK and international safety standards.

Intra-Plant Communication

Integrated controls extend beyond the machine. Bespoke equipment must communicate with upstream and downstream systems. Interfaces enable synchronised data exchange and support traceability requirements in regulated environments.

Modular controls, expandable PLC programmes, and upgrade-ready components make it easier for clients to scale production or introduce new product lines.

Final Tests Before Dispatch

Before leaving the workshop, each machine must prove it can perform safely and reliably. Testing confirms performance, hygiene compliance, and alignment with client expectations.

Equipment Checks

Inspection begins with a full mechanical review. Frames, welds, surface finishes, and moving parts must all match the approved design. Engineers verify dimensions, tighten fasteners, and ensure all load-bearing elements meet hygiene and structural standards.

Dry Testing the Machine

The machine is powered up and run without product to confirm that motors, conveyors, belts, actuators, and safety mechanisms operate correctly. Engineers ensure the machine aligns and runs at the correct speed. Guards, emergency stops, and safety meshes are checked for correct functionality.

Automation Testing

PLC programmes, sensors, HMIs, and communication signals are tested. Engineers verify alarms, cycle sequences, start-up and shutdown routines. Sensors must detect products and adjust machine behaviour accurately and without delay. Automation testing ensures smooth integration with other line equipment.

Mock Run Testing

Sample products are introduced to simulate real production. Engineers assess flow, accuracy, and machine interaction. The controlled test environment allows issues to be identified and resolved before installation. Once the machine passes all tests, it is signed off for delivery.

Clients receive validation reports, safety test records, electrical diagrams, compliance documentation, and hygiene records.

Installation and Production Line Integration

This is the moment the client has been waiting for. Careful planning, design, fabrication, and testing culminate in seamless installation and integration with the production line.

Preparations

The installation team reviews site drawings, access routes, layouts, and other line equipment. Potential challenges—such as overhead obstructions or power availability—are identified early. If a production shut-down is required, the team coordinates with the client to minimise disruption.

Mechanical Installation

On installation day, machinery is positioned according to the final layout plan. The equipment is levelled and aligned to ensure correct performance. Drainage and washdown systems depend on precise levelling, so this step is handled carefully.

Electrical and Control Integration

Electrical integration follows mechanical installation. The team connects machinery to power, control panels, and communication systems. PLCs, sensors, and safety circuits are linked to the rest of the line. Emergency stops, interlocks, and guards are verified for full compliance.

Commissioning and Machine Handover

Commissioning involves running the equipment under real operating conditions. Engineers confirm that every component performs as intended. Motor speeds, sensor accuracy, product flow, and automation sequences are adjusted where necessary to optimise performance.

Operators and maintenance teams attend the training to learn safe operation, cleaning, and routine checks. They must also understand early indicators of wear to prevent downtime.

Once the client is satisfied, Singleton Engineering provides a full handover, including certification, maintenance requirements, and operational guides. The machinery should now support reliable, efficient production from day one.

Speak to Singleton Engineering About Your Next Project

Ready to upgrade your production line with bespoke, food-grade engineering?

Speak to Singleton Engineering today. Our stainless steel specialists design, build, and install machinery that keeps your operation efficient, compliant, and future-ready.

Get in touch now to discuss your project requirements.