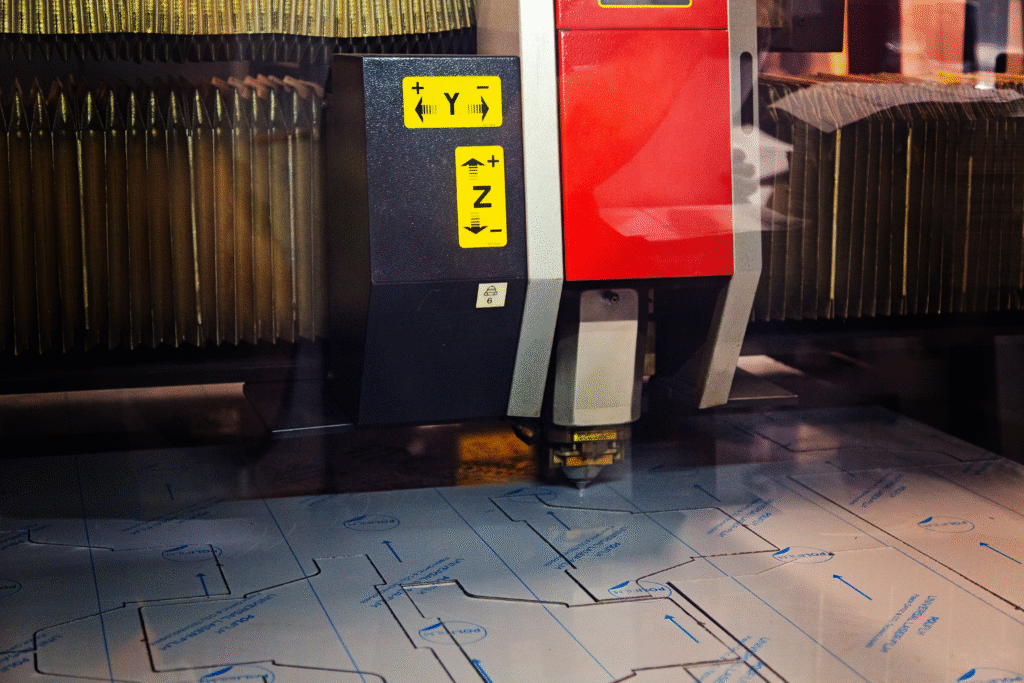

We’re not just a cutting service. Singleton is a full engineering partner with experience in fabrication, mechanical fitting and electrical integration. That means the parts we laser profile are designed to work in the real world, not just look good on a drawing.

From one-off laser-cut plates to high-volume production runs, we combine modern equipment with practical engineering knowledge. If you need accurate laser profiling backed by a team that understands the bigger picture, we’re ready to help.